Thyristor / Diode Discretes

-

Y50ZPC-30-12

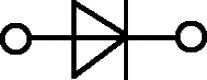

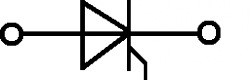

Rectifier Diodes

VRRM: 1200 (V)

IFAV: 3000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y50ZPC-30-14

Rectifier Diodes

VRRM: 1400 (V)

IFAV: 3000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y50ZPC-30-16

Rectifier Diodes

VRRM: 1600 (V)

IFAV: 3000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y50ZPC-30-18

Rectifier Diodes

VRRM: 1800 (V)

IFAV: 3000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y50ZPC-30-20

Rectifier Diodes

VRRM: 2000 (V)

IFAV: 3000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y65KKE-20-12

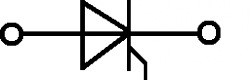

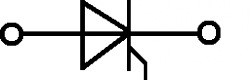

Fast Turn-off Thyristors

VRRM: 1200 (V)

ITAV: 2000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y65KKE-20-14

Fast Turn-off Thyristors

VRRM: 1400 (V)

ITAV: 2000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y65KKE-20-16

Fast Turn-off Thyristors

VRRM: 1600 (V)

ITAV: 2000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y65KKE-20-18

Fast Turn-off Thyristors

VRRM: 1800 (V)

ITAV: 2000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost -

Y65KPC-30-06

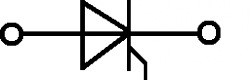

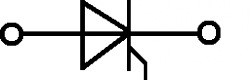

Phase Controlled Thyristors

VRRM: 600 (V)

ITAV: 3000 (A) VAT not applicable

VAT not applicable

excl. Shipping Cost

More information about thyristor & diode discrete

A discrete structure is defined as a structure consists of sole diodes, transistors and thyristors and has no integrated circuits. The individual components are soldered on the semiconductor plate. Where the modules are no longer sufficient, the disc cells / capsules can be used. The disc cells have no insulation within them and can be cooled on both sides. Thus, due to the two-sided heat dissipation they are especially suitable for operation between two heatsinks. A thyristor disc cells has an optimal thermal and electrical contact to the heat sink. Such things can, however, also easily reached from internal component.

The name disc cells derives, whether equipped with a thyristor or diode, from the round and flat, disk-like shape. Here, a thyristor or diode will be placed on a wafer between two plungers, which are a cathode and an anode. This wafer chip is round and favors the disk shape. The wafer chip is fabricated in a clean room from silicon to achieve the optimal quality in the disc cells.

The disc cell is encased in a ceramic housing. In order to distribute evenly the pressure on the wafer and the thyristor as well as on the anode, and to achieve an optimal adaptation to the material expansion, the wafer made of silicon will be placed between two slices of molybdenum. The welding of the two closure plates as the ceiling and bottom hermetically closes the complete disc cell. Only when the disc cell is subjected to a certain pressure, a thermal and electrical contact between anode and cathode can be realized and the diode or thyristor dedicates to the task put to him.

Therefore, the disc cells are an excellent choice for soft starter device, as well as for induction heating, welding equipment, DC power systems and electricity utilities. Using a soft starter the final consumption for on switching of the device can be reduced, and for the devices with mechanical reaction forces such as grinding machines, these can be also minimized. The electrical motors and other machines with strong or large torque can thus additionally be protected against overly large input acceleration and the direct response of a power protection can be then bypassed.